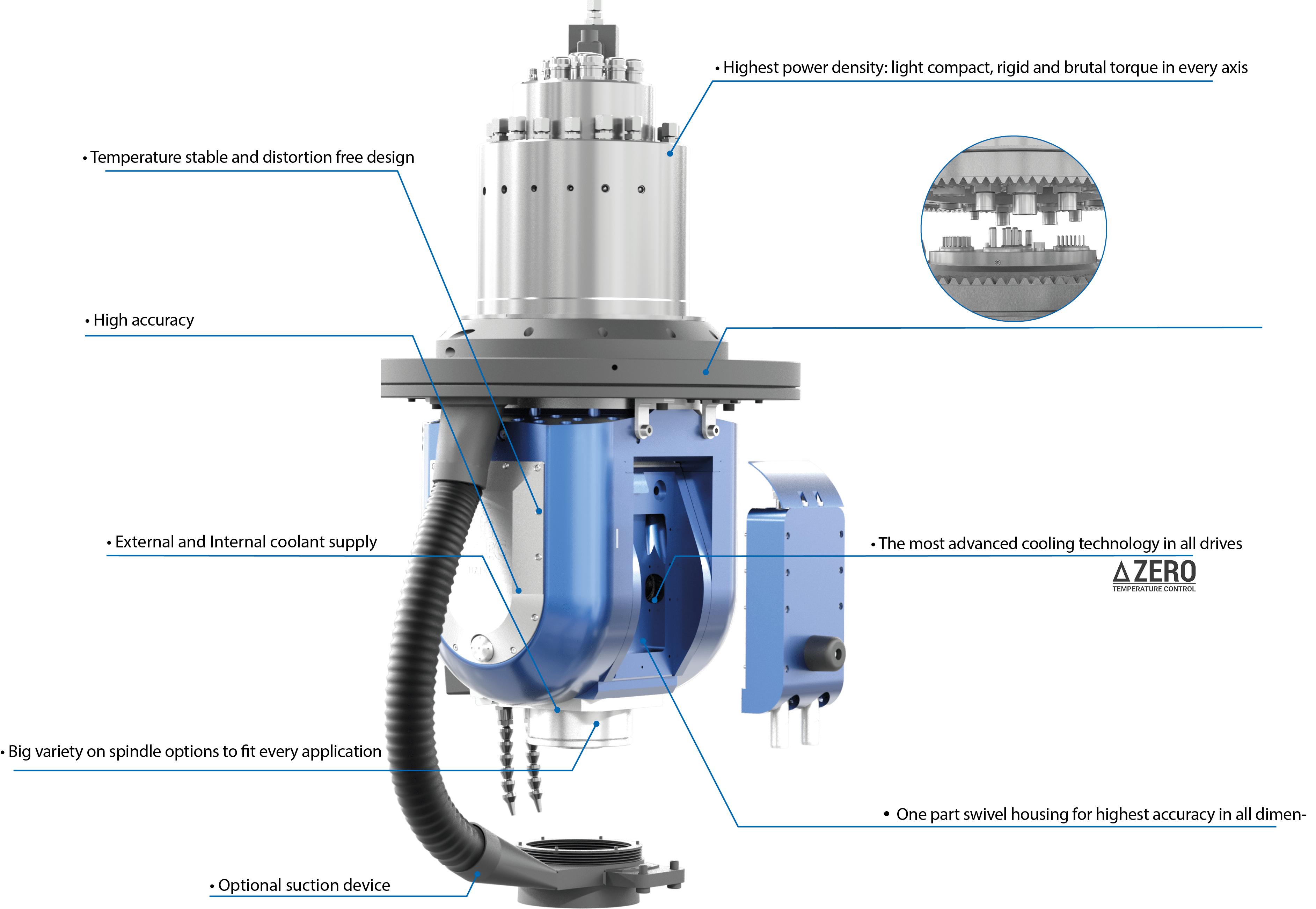

Decades of experience in developing milling heads with direct drive technology enable our customers to benefit from a major technological edge.Our product range comprises precise and extremely reliable machine heads distinguished by high dynamic performance.Our universal milling heads with direct drive technology excel with incredibly fast acceleration values and unprecedented precision. Positioning accuracy is around 0.0005°. CYTEC offers you a wide range of configuration options that can be individually tailored to your requirements. Compact and flexible milling heads mean greater utilisation of the available workspace. Combined with our innovative drive technology, you can fully exploit the potential of our swivel milling heads. Thanks to the integration of cutting-edge spindle technology by CYTEC, this results in a highly productive system. Here, our spindles can be used for both pure milling, as well as for rotational milling.

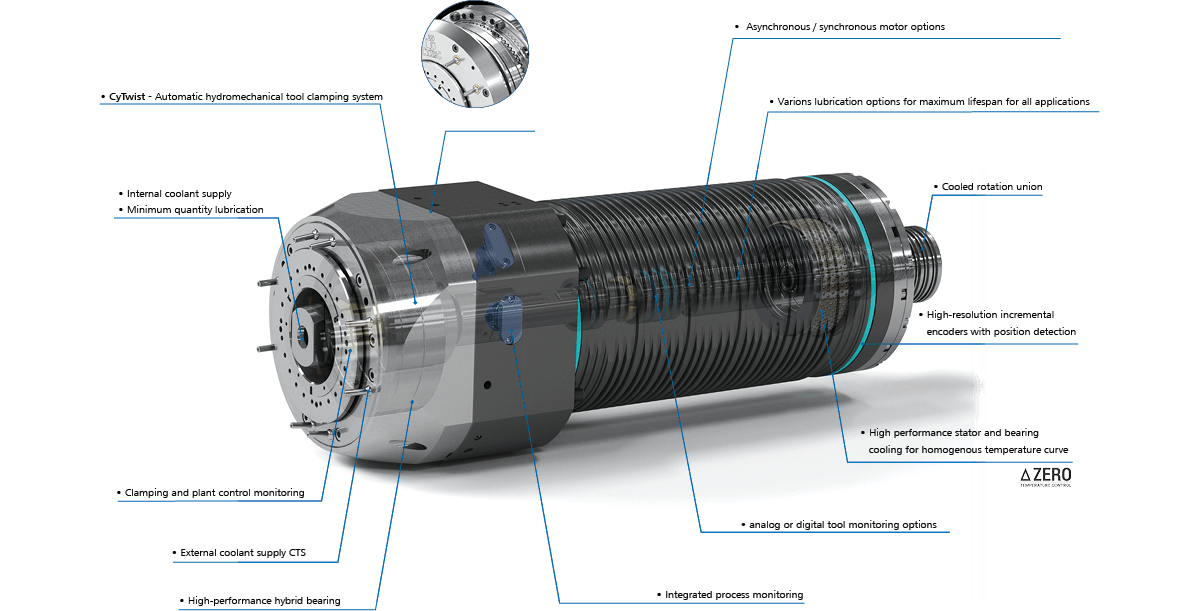

CYTEC's modular motor-driven spindles from the "modular kit" can be configured specifically for your application and manufactured per customer specifications; this covers almost the entire spectrum of conceivable processing tasks from:

asynchronous/synchronous motors with a performance range from 8 to 76 kW

planetary gear allows torque values of up to a maximum of 1,150 Nm

CYTEC optimized them once more as latest generation of direct drives for rotating and swivel axes.

Destinctive chracteristics of the series are performance, precision and a high amount of reliability together with enormous power and dynamic. The advantages benefit not only ambitious machining operation, but especially the high speed-turning up to 1.000 rpm.

CYTEC optimized them once more as latest generation of direct drives for rotating and swivel axes.

Destinctive chracteristics of the series are performance, precision and a high amount of reliability together with enormous power and dynamic. The advantages benefit not only ambitious machining operation, but especially the high speed-turning up to 1.000 rpm.

IMPRINT

PRIVACY